- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

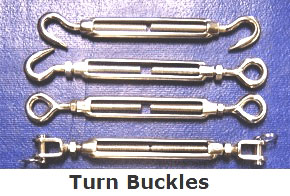

Rope Services Direct supply a range of rigging screws and turnbuckles. They come with a variety of fittings for each end to suit your particular application, for example; eye +eye, eye + hook, jaw + jaw, Hook + jaw, etc. Some rigging screws are fitted with locking nuts/barrel strainers to ensure that there is no unwanted loosening of the rope.

All rigging screws can be used for tensioning tasks, however not all can be used for lifting purposes so please ensure you check the details carefully.

As standard we supply 5MM, 6MM, 8MM and 10MM screws in mild and stainless steel, Some are available from M4 up to M20 sizes. But please do ask us if you need anything custom-made. As well as standard commercial galvanized and stainless steel tensioning products we also supply Green Pin turnbuckles as well a some US style rigging screws so we have something to suit every pocket and scenario.

We are always available for clarification on any wire rope fitting and for order taking on 01384 78004, we look forward to hearing from you!

£1.26

Stainless Turnbuckle eye & eye – practical and strongIdeal for outdoor ..

£1.24

What Are Hook and Eye Turnbuckles?These turnbuckles consist of a central body wi..

£1.33

Stainless Turnbuckle hook & hook – functional and non-corrosionOur rang..

£3.12

Stainless Turnbuckle jaw & jaw This particular type of stainless turnbuckle..

£3.80

What Are Jaw-End Turnbuckles?A turnbuckle consists of a central threaded body ..

£2.77

About Turnbuckle with Eye & Eye – US Style These US style turnbuckles are ..

£3.08

About the Turnbuckle with Eye and Jaw US Style Made from drop forged, high te..

POA

About the Rigging Screw with Jaw & Eye All models are hot dipped galva..

POA

Understanding Closed Body Rigging Screw with Jaw and Jaw Made from high qua..

POA

Stainless Lifting rigging screw with Eye & Eye SpecificsThe basics at a gla..

POA

Rigging Screw with Eye & Eye Facts Manufactured from mild steel the ..

POA

About Stainless Lifting Rigging Screw with Jaw & EyeStarting at 200kg work..

POA

Stainless Lifting Rigging Screw with Jaw & Jaw Details These 316 stainless..

POA

Stainless Rigging screw Jaw & Jaw – lasting and versatileStainless rigging s..

POA

Stainless Rigging Screw Toggle & Swage Stud – ideal for marine conditionsAls..

POA

Stainless Rigging screw welded jaw & swage stud – professional grade and rel..

POA

Stainless Rigging screw swage swage – robust and weather resistantAlso refe..

POA

About Green Pin Turnbuckle with Jaw & Jaw Providing professional rigging ..

POA

Green Pin Turnbuckle with Eye & Eye SizesThe Green Pin Turnbuckle with eye &..

POA

Green Pin Turnbuckle with Jaw & EyeThe Green Pin Eye jaw Turnbuckle represe..

POA

Green Pin Turnbuckle with Hook & Hook Design The hook fitting at each end..

Turnbuckles and/or rigging screws are commonly used in rigging applications and anywhere that the wire will need tightening. Usually to a unique rigidity to fit its objective, for example, bridges, balustrades, staircases and hanging shelves. They are often utilised for use as barriers (instead of fencing) to avoid access to certain areas. Or sometimes as a safety barrier, but are easy on the eye. For example they are used on castle ramparts to allow the public to be able to walk around them safely. Yet they do not intrude too much on the original nature of the buildings.

Other than the traditional uses in marine rigging and architectural applications, rigging screws and turnbuckles find extensive use in theatrical rigging. Precise tensioning of flying systems and backdrop supports is essential for safety. The entertainment industry commonly uses these types of fittings, especially when touring, where quick setup and reliability is essential.

Other uses include agricultural settings, where farmers may use rigging screws for tensioning fence lines to keep livestock contained. Consistent tension prevents sagging that could compromise security. The adjustability feature allows for seasonal expansion and contraction. whilst maintaining fence security.

Turnbuckles and rigging screws are typically used for tensioning tasks, however some products can be used for lifting applications too like the Green Pin tensioners.

There are a number of different options to consider when choosing your tensioning product but the material they are made from and the quality can make all the difference. Commercial, galvanized tensioners are ideal for more industrial applications. Stainless steel tensioners are more suited to outdoor or clean environments or public areas as they are more appealing to look at. Probably one of the best known types of rigging fittings are the Green Pin branded products ; known for their quality, strength and durability. Additionally they are capable of lifting as well as tensioning thus, used across the world. For similar specification products with typically lower price tags are the US style turnbuckles - find them above and compare away.

Rigging screws have the closed barrel type centre and so look more aesthetically pleasing whilst Turn buckles have an open body/centre piece which turns around the visible screws. The definition of a turn buckle is type of coupling which possesses internal screws that are used to connect two wires or rods, end to end in order to adjust the tension.

Rigging Screws

Rigging Screws are usually used for the tightening/ tensioning of wire ropes. These types of wire rope fittings are frequently utilised for rigging tasks or wherever a rope may require tensioning to a specific rigidity, for example; bridge wires, stair balustrades, barriers/fences or hanging/floating shelving. They are designed for in-line & straight rigging and tensioning & are available in different combinations including Eye & Eye & Eye & Jaw. These are available in different sizes in mild steel or stainless steel.

When choosing between galvanised steel and stainless steel rigging screws your choice will depend on your environment and budget considerations. Mild galv. steel options provide high strength, typically at lower prices, thus ideal for indoor tasks or temporary installations where corrosion resistance isn't necessary. However, should you need them for marine type environments, outdoor installations, or other high moisture areas, stainless steel rigging screws are the best option as they offer optimum corrosion resistance.

When fitting rigging screws and turnbuckles, proper setup is necessary for safety. Prior to installation, always inspect each component thoroughly for any signs of damage, corrosion, or manufacturing defects. These checks can prevent potential failures that could compromise the whole rigging set up.

Load requirements is an important factor to consider when selecting the appropriate rigging screw or turnbuckle for your application. The working load limit (WLL) should never exceed the manufacturer's specifications. Applying appropriate safety factors is highly recommended and will depend on how you intend to use them. For critical applications such as public access areas, we recommend using higher safety margins to account for unforeseen problems.

Regular inspections should take place, before, during and after use. For high-traffic areas or safety-critical applications, monthly inspections are highly recommended. Check for thread wear, corrosion, and proper adjustment for the correct tension. The threads should move freely without any binding.

If corrosion is detected early enough, a proper clean and re-lubrication can sometimes restore full functionality. However, any rigging screw or turnbuckle shows thread damage, cracks, or excessive wear should be discarded and replaced immediately.

At Rope Services Direct, we understand that standard configurations don't always meet every application requirement. Our technical team can usually help with custom combinations, special materials, or non-standard sizes to suit your specifications. Whether you're dealing with building restoration or industrial applications requiring specific load ratings, we can provide tailored solutions.

For technical guidance or to discuss your specific requirements, our experienced team is available on 01384 78004. We're committed to ensuring you select the right rigging hardware and other rope fittings for your application, providing both technical expertise and competitive pricing to support your project success.