- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

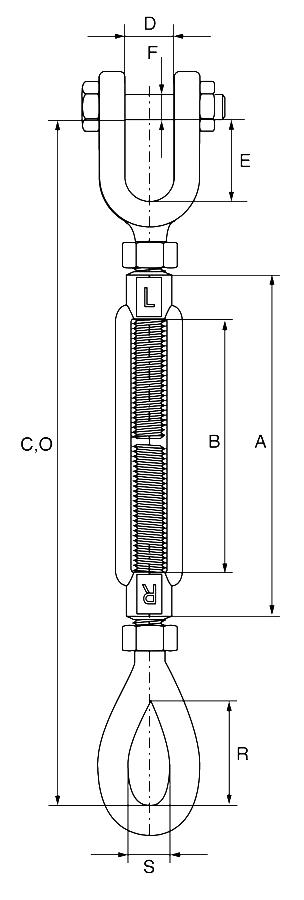

A turnbuckle with eye and jaw US style configuration is a galvanised, versatile rigging component that combines two different end configurations in a single unit. One end features a jaw (fork-like opening) while the other has an eye (closed loop). Available with working load limits up to 34 tonnes.

Made from drop forged, high tensile steel the turnbuckle with eye and jaw set up in US style specifications has been hot dipped galvanized and thus boasts excellent corrosion resistance, strength and durability properties.

When it comes to physical size our range of these turnbuckles start at ¼ inch and go up to 2 3.4 inch with UNC (unified national coarse) threads in US fed spec style (now known as ASTM F1145-92).

Safety wise all turnbuckles up to 5/8” have safety bolts to lock securely. For 3/4” and above cotter pins are used for additional security.

Easily identifiable thanks to the clear markings which include the WLL, size, ID, CE & UKCA marks, tracing code and left and right markings. Material traceability and declaration of conformity certification can be provided.

Rope Services Direct can supply a range of turnbuckles in the US style with various end terminals such as jaw and jaw, or eye and eye. We also have a great range of stainless steel turnbuckles and rigging screws to choose from should you need the stainless option.

|

Product Code |

Size |

Take Up |

W.L.L. |

A |

B |

D |

E |

F |

R |

S |

C |

O |

Weight |

|

|

inches |

inches |

t |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kgs |

|

TBJE6X4 |

¼ |

4 |

0.23 |

120 |

102 |

11.5 |

15.75 |

7.5 |

20 |

8.5 |

215 |

307 |

0.14 |

|

TBJE8X4.5 |

5/16 |

4 1/2 |

0.36 |

138 |

114 |

12.7 |

21.2 |

7.6 |

24 |

11.2 |

249 |

354 |

0.2 |

|

TBJE10X6 |

3/8 |

6 |

0.54 |

180 |

152 |

13.7 |

21.5 |

9 |

28.5 |

13.5 |

308 |

460 |

0.34 |

|

TBJE12X6 |

½ |

6 |

1 |

190 |

152 |

16 |

26.5 |

11 |

36.5 |

18 |

380 |

532 |

0.71 |

|

TBJE12X9 |

½ |

9 |

1 |

267 |

229 |

16 |

26.5 |

11 |

36.5 |

18 |

456 |

685 |

0.85 |

|

TBJE12X12 |

½ |

12 |

1 |

343 |

305 |

16 |

26.5 |

11 |

36.5 |

18 |

510 |

815 |

1 |

|

TBJE16X6 |

5/8 |

6 |

1.59 |

203 |

152 |

21 |

33 |

14 |

45 |

22.5 |

398 |

550 |

1.17 |

|

TBJE16X9 |

5/8 |

9 |

1.59 |

279 |

229 |

21 |

33 |

14 |

45 |

22.5 |

474 |

703 |

1.42 |

|

TBJE16X12 |

5/8 |

12 |

1.59 |

355 |

305 |

21 |

33 |

14 |

45 |

22.5 |

550 |

855 |

1.67 |

|

TBJE19X6 |

¾ |

6 |

2.36 |

213 |

152 |

26 |

37.25 |

17.5 |

53 |

25.4 |

448 |

600 |

1.87 |

|

TBJE19X9 |

¾ |

9 |

2.36 |

289 |

229 |

26 |

37.25 |

17.5 |

53 |

25.4 |

524 |

753 |

2.22 |

|

TBJE19X12 |

¾ |

12 |

2.36 |

365 |

305 |

26 |

37.25 |

17.5 |

53 |

25.4 |

600 |

905 |

2.57 |

|

TBJE19X18 |

¾ |

18 |

2.36 |

517 |

457 |

26 |

37.25 |

17.5 |

53 |

25.4 |

752 |

1209 |

3.27 |

|

TBJE22X12 |

7 |

12 |

3.27 |

374 |

304 |

31 |

42.75 |

20.5 |

60 |

32 |

630 |

934 |

3.77 |

|

TBJE22X18 |

7/8 |

18 |

3.27 |

527 |

457 |

31 |

42.75 |

20.5 |

60 |

32 |

782 |

1239 |

4.7 |

|

TBJE25X6 |

1 |

6 |

4.54 |

233 |

152 |

33 |

52 |

24 |

76 |

37 |

552 |

704 |

4.1 |

|

TBJE25X12 |

1 |

12 |

4.54 |

385 |

305 |

33 |

52 |

24 |

76 |

37 |

704 |

1009 |

5.33 |

|

TBJE25X18 |

1 |

18 |

4.54 |

537 |

457 |

33 |

52 |

24 |

76 |

37 |

856 |

1313 |

6.56 |

|

TBJE25X24 |

1 |

24 |

4.54 |

690 |

610 |

33 |

52 |

24 |

76 |

37 |

1010 |

1620 |

7.83 |

|

TBJE32X12 |

1.1/4 |

12 |

6.89 |

388 |

305 |

47 |

70.5 |

31 |

90 |

46 |

776 |

1081 |

9.1 |

|

TBJE32X18 |

1.1/4 |

18 |

6.89 |

541 |

457 |

47 |

70.5 |

31 |

90 |

46 |

928 |

1385 |

10.94 |

|

TBJE32X24 |

1.1/4 |

24 |

6.89 |

693 |

610 |

47 |

70.5 |

31 |

90 |

46 |

1080 |

1690 |

12.75 |

|

TBJE38X12 |

1.1/2 |

12 |

9.71 |

403 |

305 |

47 |

70.5 |

31 |

103 |

53.8 |

838 |

1143 |

12.93 |

|

TBJE38X18 |

1.1/2 |

18 |

9.71 |

555 |

457 |

57 |

70.5 |

37 |

103 |

53.8 |

990 |

1447 |

15.43 |

|

TBJE38X24 |

1.1/2 |

24 |

9.71 |

708 |

610 |

57 |

70.5 |

37 |

103 |

53.8 |

1144 |

1754 |

17.97 |

|

TBJE44X18 |

1.3/4 |

18 |

12.7 |

571 |

457 |

66 |

85 |

44 |

117 |

60.5 |

1076 |

1544 |

23.37 |

|

TBJE44X24 |

1.3/4 |

24 |

12.7 |

724 |

610 |

66 |

85 |

44 |

117 |

60.5 |

1230 |

1840 |

26.91 |

|

TBJE50X24 |

2 |

24 |

16.78 |

740 |

610 |

66.3 |

92 |

54 |

146 |

68 |

1400 |

2010 |

39.93 |

|

TBJE63X24 |

2.1/2 |

24 |

27.22 |

795 |

610 |

78 |

110.8 |

60.5 |

165 |

79 |

1490 |

2100 |

70.96 |

|

TBJE70X24 |

2.3/4 |

24 |

34.02 |

795 |

610 |

93.5 |

104.5 |

73 |

178 |

82.5 |

1562 |

2172 |

82.22 |