Round Slings Design

Round slings help protect more delicate loads from damage, offering protection to surface finishes. Unlike chain or wire rope slings, they won't scratch, dent, or damage your valuable loads. The soft construction also conforms to the shape of the load, distributing weight evenly and reducing stress points.

This is due to the soft and flexible nature of these round slings which are made from 100% polyester webbing with a padded inner core.

The seamless tubular cover is non-load bearing and acts as a protective cover around the load bearing core. The polyester round sling covers have excellent wear and abrasion resistance over its entirety partly because there are no seams or edges to rub against loads and components, it is often edges and seams which wear out first.

The inner core is the load bearing part. The round sling core is made from polyester yarn hank which is twisted and wound together. This provides great strength and durability. These slings will flatten somewhat during use to better grip the load; this will not detract from its safe working load.

Polyester Round Sling Properties & Uses

Polyester material offers excellent resistance to stretching and maintains its strength even in challenging conditions. Polyester also has good resistance to UV light, many chemicals and mildew; it is quick drying, abrasion resistant and easy to clean.

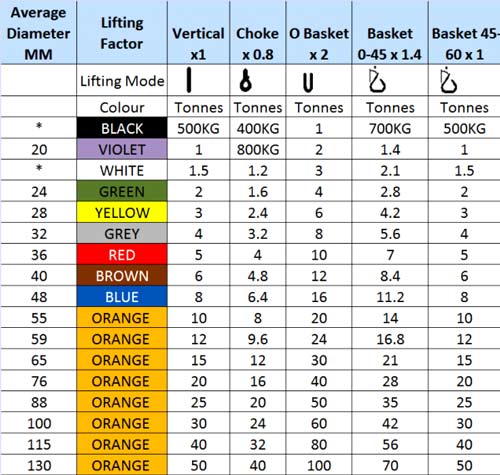

Round slings are used all over the place including manufacturing, construction, warehousing, and marine industries. They're perfect for lifting all manner of loads where surface protection matters. Their flexibility allows use in various configurations including vertical, choker, and basket hitches. Some hitches will affect the WLL so please refer to the slinging chart.

These slings are lightweight and easy to handle. Color-coded sleeves indicate different weight ratings, making capacity identification quick and preventing dangerous overloading.

Round Sling Colour system

The slings are available in a range of widths and

safe working loads and lengths from 1 to 6 meters (or 12 meter circumference) as standard. The standard colour coding format applies to all our round

slings in order to easily identify the safe working load of the sling.

- 1 tonne = purple

- 2 tonne = green

- 3 tonne = yellow

- 4 tonne = grey

- 5 tonne = red

- 6 tonne = brown

- 8 tonne = blue

- 10 tonne = orange.

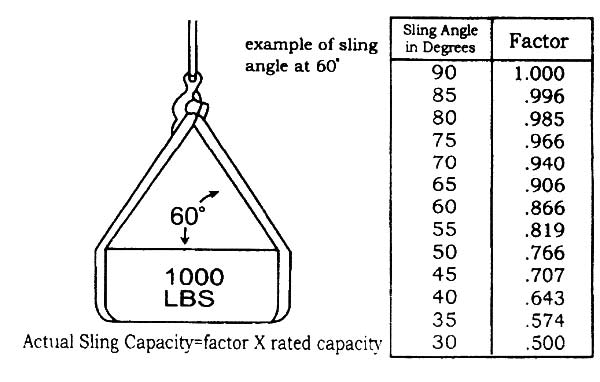

Safe Slinging Practices

As with all lifting slings safe

slinging procedures must be followed at all times. The angle of the lift (this is the angle the sling takes from

a vertical plane) , hitch type and safe working load should all be taken into consideration. The chart below

should help to identify the reduction required to the SWL at various angles and with each hitch type.

Call Rope Services Direct today on 01384 78004 or use our contact us

form to place your order or to clarify any questions. Find out more about us on the Rope Services Direct About Us Page.

Safe use of Round slings

- Slings used in a basket hitch must have the load balanced to prevent slippage.

- Slings must always be protected from sharp edges, protrusions or abrasives

- Determine the weight of the load, which must be within the rated capacity of the sling.

- Slings with fittings used a choker hitch must be of such a length to assure that the choking action is on

the webbing, and never on a fitting.

- The opening fittings must be the proper shape and size to ensure that the fitting will seat correctly in the

hook.

- Select sling having suitable characteristics for the type of load, hitch and environment.

- Don’t load a sling in excess of the rated capacity. Taking into account the load angle which effects the

rated capacity.

- Do not drag slings on floors or abrasive surfaces. Don’t twist or tie slings or join in knots.

- Slings shall not be pulled from under loads if load is resting on sling.

- When lifting in a chemically active environment, make sure sling materials are compatible with each

chemical.

- Do not drop slings with metal fittings

- Don’t pull on the sling when loaded.

More Tips

- Never store wet slings, clean with water and dry thoroughly, ALWAYS store in a cool dry dark place.

- Sun/ultraviolet light degrades the strength of slings.

- Hitch the sling in a manner providing control of the load.

- Personnel must keep clear of the suspended load, and from between the sling and load, and between sling and

crane/hoist hook.

- Personnel must not ride the sling

- Don’e use a sling at temperatures above 80⁰c or below 0⁰c

- Do not shock load

- Do not twist or kink legs.

- Loads must be centred in base of hook.

- Slings must be long enough so that the rated capacity is adequate. Including when the angle of the legs is

taken into account.

- The sling legs shall contain or support the load from the sides above the centre of gravity when using a

basket hitch.

SLING ANGLE AND SLING LOAD CHART

The sling angle is the angle measured between a horizontal line and the sling leg or body. This angle is very

important and can have a dramatic effect on the rated capacity of the sling. As shown, when this angle

decreases the load on each leg increases. This principal applies whether one sling is used to pull at an angle.

In a basket hitch, or for multi-legged bridle slings. This data is only for equally loaded sling legs. Do not

use angles of less than 30 degrees.

INSPECTING YOUR ROUNDSLINGS:

INITIAL INSPECTION:

Before any new or repaired sling goes into service it needs an initial inspection. A designated person should

ensure that the correct sling is being used. They should also determine that the slings meet the requirements

and has not been damaged in shipping.

FREQUENT INSPECTIONS:

Before every use of a sling a frequent inspection should be made for fault finding purposes.

PERIODIC INSPECTIONS:

This is a thorough inspection which is carried out by competent personnel. The frequency of inspection should be

based on:

Frequency of sling use.

Severity of service conditions.

Experience gained on the service life of slings used in similar applications.

Carry out thorough inspections every 6 months. Records of inspections must be kept on file.

Examine slings prior to every use. Look for signs of deterioration including, snagging, holes, tears, cuts,

broken or worn stitching, knots, burns or excessive abrasive wear.

Rope Services Direct can also supply other types of lifting slings, including flat web slings, wire rope slings and chain slings.