- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wire has a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

POA

The characteristics of 17x7 non-rotating wire ropeAll ropes that have been manuf..

POA

19x7 Rotation Resistant Wire Rope Full product information Non-rotating rop..

POA

The details for the 24x7 Rotation Resistant Wire RopeFor the majority of operati..

POA

Product information for the 25x7 Rotation Resistant Wire RopeEquipment such as t..

POA

Everything that you need to know about our 28x7 non-rotating wire ropeOur non-ro..

POA

Full product information for the 32x7 non-rotating wire rope Non-rotating e..

POA

Our 34x7 non rotating wire ropeConstructed from strong and corrosion resistant s..

POA

Product details; 35x7 non-rotating wire ropeThis equipment rope is constructed f..

POA

How does 36x7 non-rotating wire rope work?A piece of 36x7 non-rotating wire rope..

Various classes of non-rotating wire-rope are available such as 18x7 and 19x7. Call us today on 0138478004 to discuss your application and we can advise on a solution for you.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope, crane rope, off-shore and deck rope and more.

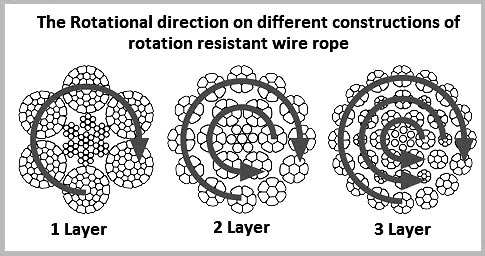

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unravelling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular, thorough inspections of non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see. Rope Services Direct offer inspections on all rope with certification issued on completion.

Rotation resistant rope should avoid shock loading. This is because rope distortions, bird caging and core protrusion can occur.

Holding both ends of the rope will prevent unravelling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

Rope Services Direct can supply non rotating wire rope to your specifications at the most reasonable prices so call us today on 01384 78004.