- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

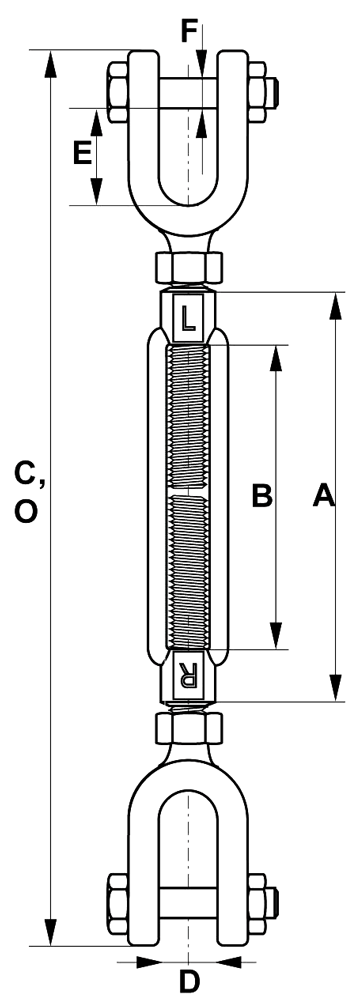

These turnbuckles with a jaw at each end are manufactured to the popular US style and are galvanized for good corrosion protection. Available in sizes up to 2 ¾ inch, with 34 tonne capacities.

A turnbuckle consists of a central threaded body with attachments at each end. Jaw-end turnbuckles feature fork-like openings that can accommodate shackles, eye bolts, rope with a formed eye or other suitable end fitting as well as other hardware. This design makes them particularly useful when you need to connect two objects or to existing anchor points, they are also ideal when frequent adjustment to the tension is required.

The main turnbuckle body has an open design and contains both right-hand and left-hand threaded screws, allowing simultaneous adjustment when rotated. One jaw end connects to a right-hand threaded rod, while the other connects to a left-hand threaded rod. The opposite threading enables users to tighten or loosen the assembly by turning the central body in either direction.

The jaw ends enable a number of different connectors of various sizes to be fitted such as shackles, or wire rope with thimble eye end terminations.

US style jaw-end turnbuckles are commonly used in applications requiring frequent adjustments or temporary connections. They're commonly found in:

Cable and wire rope rigging systems

Structural bracing and guy-wire installations

Marine rigging for sailboats and yachts

Fence tensioning systems

At Rope Services Direct we understand that no two tasks are the same, thus we offer a wide range of turnbuckles and rigging screws with various end fitting to suit a wider ran of applications. A stainless steel version of this turnbuckle is also available.

If turnbuckles or rigging screws are not quite right for your needs then take a look at some of our other rope fittings where you will find rope grips, sockets, shackles, swaged and swageless terminals and many more. We also have our own workshop where swaged terminations can be accommodated as well as thimble eyes and other wire rope assemblies.

|

|

|||||||||||

|

Product Code |

Size |

Take Up |

W.L.L. |

A |

B |

D |

E |

F |

C |

O |

Weight |

|

|

inches |

inches |

t |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kgs |

|

TBJJ6X4 |

¼ |

4 |

0.23 |

120 |

102 |

11.5 |

15.75 |

7.5 |

200 |

302 |

0.16 |

|

TBJJ8X4.5 |

5/16 |

4 1/2 |

0.36 |

138 |

114 |

12.7 |

21.2 |

7.6 |

244 |

358 |

0.24 |

|

TBJJ10X6 |

3/8 |

6 |

0.54 |

180 |

152 |

13.7 |

21.5 |

9 |

290 |

442 |

0.71 |

|

TBJJ12X6 |

½ |

6 |

1 |

190 |

152 |

16 |

26.5 |

11 |

330 |

482 |

0.37 |

|

TBJJ12X9 |

½ |

9 |

1 |

267 |

229 |

16 |

26.5 |

11 |

406 |

635 |

0.79 |

|

TBJJ12X12 |

½ |

12 |

1 |

343 |

305 |

16 |

26.5 |

11 |

480 |

785 |

1.09 |

|

TBJJ16X6 |

5/8 |

6 |

1.59 |

203 |

152 |

21 |

33 |

14 |

378 |

530 |

1.35 |

|

TBJJ16X9 |

5/8 |

9 |

1.59 |

279 |

229 |

21 |

33 |

14 |

454 |

683 |

1.53 |

|

TBJJ16X12 |

5/8 |

12 |

1.59 |

355 |

305 |

21 |

33 |

14 |

530 |

835 |

1.79 |

|

TBJJ19X6 |

¾ |

6 |

2.36 |

213 |

152 |

26 |

37.25 |

17.5 |

422 |

574 |

1.99 |

|

TBJJ19X9 |

¾ |

9 |

2.36 |

289 |

229 |

26 |

37.25 |

17.5 |

498 |

727 |

2.48 |

|

TBJJ19X12 |

¾ |

12 |

2.36 |

365 |

305 |

26 |

37.25 |

17.5 |

574 |

879 |

2.68 |

|

TBJJ19X18 |

¾ |

18 |

2.36 |

517 |

451 |

26 |

37.25 |

17.5 |

726 |

1183 |

3.32 |

|

TBJJ22X6 |

7/8 |

6 |

3.27 |

222 |

152 |

31 |

42.75 |

20.5 |

466 |

618 |

3.15 |

|

TBJJ22X12 |

7/8 |

12 |

3.27 |

374 |

304 |

31 |

42.75 |

20.5 |

618 |

922 |

3.96 |

|

TBJJ22X18 |

7/8 |

18 |

3.27 |

527 |

457 |

31 |

42.75 |

20.5 |

770 |

1227 |

5.09 |

|

TBJJ25X6 |

1 |

6 |

4.54 |

233 |

152 |

33 |

52 |

24 |

510 |

662 |

4.44 |

|

TBJJ25X12 |

1 |

12 |

4.54 |

385 |

305 |

33 |

52 |

24 |

662 |

967 |

5.69 |

|

TBJJ25X18 |

1 |

18 |

4.54 |

537 |

457 |

33 |

52 |

24 |

814 |

1271 |

6.74 |

|

TBJJ25X24 |

1 |

24 |

4.54 |

690 |

610 |

33 |

52 |

24 |

966 |

1576 |

8.03 |

|

TBJJ32X6 |

¼ |

6 |

6.89 |

236 |

152 |

47 |

70.5 |

31 |

598 |

598 |

8.55 |

|

TBJJ32X12 |

¼ |

12 |

6.89 |

388 |

305 |

47 |

70.5 |

31 |

750 |

1055 |

10.27 |

|

TBJJ32X18 |

¼ |

18 |

6.89 |

541 |

457 |

47 |

70.5 |

31 |

902 |

1359 |

11.99 |

|

TBJJ32X24 |

¼ |

24 |

6.89 |

693 |

610 |

47 |

70.5 |

31 |

1054 |

1664 |

13.69 |

|

TBJJ38X12 |

½ |

12 |

9.71 |

403 |

305 |

57 |

70.5 |

37 |

800 |

1105 |

13.56 |

|

TBJJ38X18 |

½ |

18 |

9.71 |

555 |

457 |

57 |

70.5 |

37 |

952 |

1409 |

16.2 |

|

TBJJ38X24 |

½ |

24 |

9.71 |

708 |

610 |

57 |

70.5 |

37 |

1104 |

1714 |

18.88 |

|

TBJJ44X18 |

1 ¾ |

18 |

12.7 |

571 |

457 |

66 |

85 |

44 |

1046 |

1503 |

25.15 |

|

TBJJ44X24 |

1 ¾ |

24 |

12.7 |

724 |

610 |

66 |

85 |

44 |

1198 |

1808 |

28.06 |

|

TBJJ50X24 |

2 |

24 |

16.8 |

740 |

610 |

66.3 |

92 |

54 |

1340 |

1950 |

43.71 |

|

TBJJ63X24 |

2 ½ |

24 |

27.2 |

795 |

610 |

78 |

110.8 |

60.5 |

1478 |

2088 |

81.8 |

|

TBJJ70X24 |

2 ¾ |

24 |

34 |

795 |

610 |

93.5 |

104.5 |

73 |

1562 |

2172 |

95.14 |