- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

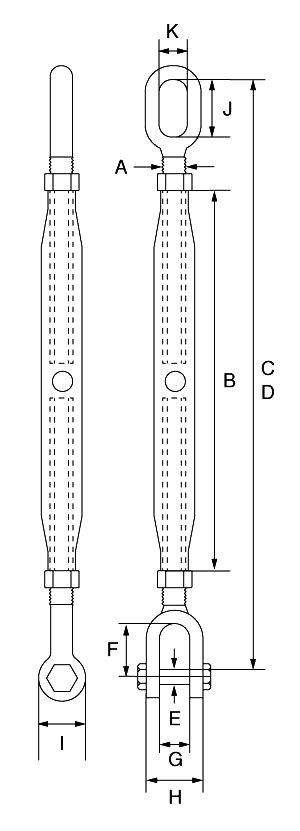

This closed body rigging screw with Jaw & eye is galvanized for better corrosion protection and comes in a range of working load limits from 0.2 tonne up to 11 tonne.

All models are hot dipped galvanized apart from the smallest two which are electro-galvanized. This dual sided rigging screw incorporates a jaw fitting at one end and a closed eye at the other, therefore different anchoring points and attachment fittings can be used. The opposite ends are threaded differently so that a simple turn of the centre barrel will increase or decrease the length in tandem. (depending on which way you turn the barrel).

The overall design of these rigging screws means they are ideal for professional rigging applications. They have a better looking finish when compared to open turnbuckle tensioners. For this reason they are often used for tensioning wire rope in balustrade systems, in gardens, on decking of for any other type of rope barrier, where aesthetics is important. The stainless steel option will look even better.

The metric thread system ensures compatibility with other hardware in the UK and EU and is clearly marked with the WLL, makers ID. Trace code and CE/UKCA compliance marks. Documentation available.

Rope tensioners come in two common formats – rigging screws and turnbuckles. They operate in the same way, however turnbuckles tend to be able to handle more load/tension than rigging screws.

When it comes to other rope fittings, there are many, visit our main fittings page to find products like wire rope grips, thimbles, terminals, swivel fittings, sockets, ferrules and many more. If you are not sure what would be the best for your needs then give our team a call for advice.

|

Product Code |

W.L.L. |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

Weight |

|

|

t |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kgs |

|

RSJE6 |

0.2 |

6 |

100 |

170 |

248 |

M5 |

19 |

7 |

20 |

13 |

11 |

11 |

0.13 |

|

RSJE8 |

0.32 |

8 |

108 |

189 |

273 |

M6 |

25 |

9 |

24 |

14 |

12 |

12 |

0.23 |

|

RSJE10 |

0.5 |

10 |

125 |

216 |

306 |

M8 |

26 |

10.5 |

28 |

19 |

13 |

13 |

0.38 |

|

RSJE12 |

0.7 |

12 |

195 |

323 |

478 |

M10 |

32 |

13 |

34 |

22 |

30 |

15 |

0.78 |

|

RSJE16 |

1.2 |

16 |

230 |

384 |

569 |

M12 |

39 |

18 |

42 |

28 |

40 |

20 |

1.36 |

|

RSJE20 |

1.5 |

20 |

270 |

455 |

665 |

M16 |

46 |

20 |

51 |

33 |

50 |

24 |

2.33 |

|

RSJE22 |

2.2 |

22 |

295 |

493 |

723 |

M20 |

55 |

25 |

55 |

38 |

50 |

24 |

3.01 |

|

RSJE24 |

3.2 |

24 |

325 |

552 |

802 |

M22 |

63 |

30 |

70 |

46 |

56 |

28 |

4.1 |

|

RSJE33 |

4.8 |

33 |

370 |

673 |

963 |

M30 |

85 |

38 |

82 |

60 |

70 |

35 |

9.23 |

|

RSJE39 |

6 |

39 |

400 |

718 |

1018 |

M33 |

86 |

45 |

85 |

76 |

80 |

40 |

11.1 |

|

RSJE45 |

8.5 |

45 |

400 |

760 |

1050 |

M39 |

105 |

50 |

100 |

86 |

90 |

45 |

20.8 |

|

RSJE48 |

11 |

48 |

400 |

820 |

1110 |

M45 |

120 |

58 |

118 |

92 |

100 |

45 |

24 |