- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

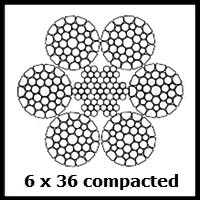

Compacted wire rope is rope which has been constructed in the same manner as other steel wire ropes equipment, except it has been tightly compacted together. If you want to find out more about the benefits of this type of construction, please read on below where you will find information regarding the 6x36 IWRC Compacted Wire Rope. Rope Services Direct can supply many different diameters from 8mmm to 52mm of this 3x36 compacted rope, see the table below for more details.

6x36 refers to the number of bundles and strands within the rope respectively. The IWRC refers to ‘independent wire rope core’, which means another construction of this equipment will sit internally, with the 6x36 strands and bundles making up the outer core. This IWRC will have its own numbered construction, say 7x7, which refers to 7 bundles and 7 strands. This means that you will effectively be left with a piece of equipment that is 6x36 + 7x7. We also stock an 8x25 compacted rope.

Once this has been constructed, the whole thing is run through a special machine in order to compact it tightly

together.

Increased lifting capabilities

Increased levels of strength

Reduced internal friction and abrasion damage

Easier to handle thanks to a smooth and more well-rounded finish

A much lower level of wire breakages

These benefits mean that 6x36 IWRC compacted wire rope is perfect for heavier lifting applications, or operations that have high breaking loads.

To place an order for this equipment, please give us a call on 01384 78004, or find all of our contact details here. If you are looking for a compacted rope for crane use then try our crane rope pages.

| 1770 | 1960 | 2160 | |||||

| Diameter | kg/100M | kN | Kg | kN | Kg | kN | Kg |

| 8 | 30.59 | 45.9 | 4,677 | 50.8 | 5,179 | 56 | 5,707 |

| 9 | 38.72 | 58.1 | 5,919 | 64.3 | 6,554 | 70.9 | 7,223 |

| 10 | 47.8 | 71.7 | 7,307 | 79.4 | 8,092 | 87.5 | 8,917 |

| 11 | 57.84 | 86.7 | 8,842 | 96 | 9,791 | 105.9 | 10,790 |

| 12 | 68.83 | 103.2 | 10,523 | 114.3 | 11,652 | 126 | 12,841 |

| 13 | 80.78 | 121.1 | 12,349 | 134.2 | 13,675 | 147.8 | 15,070 |

| 14 | 93.69 | 140.5 | 14,322 | 155.6 | 15,860 | 171.5 | 17,478 |

| 16 | 122.37 | 183.5 | 18,707 | 203.2 | 20,715 | 223.9 | 22,829 |

| 18 | 154.87 | 232 | 23,676 | 257 | 26,217 | 283 | 28,892 |

| 19 | 172.56 | 259 | 26,379 | 287 | 29,211 | 316 | 32,192 |

| 20 | 191.2 | 287 | 29,229 | 318 | 32,367 | 350 | 35,670 |

| 22 | 231.35 | 347 | 35,368 | 384 | 39,164 | 423 | 43,160 |

| 24 | 275.33 | 413 | 42,090 | 457 | 46,608 | 504 | 51,364 |

| 26 | 323.13 | 485 | 49,398 | 537 | 54,700 | 591 | 60,282 |

| 28 | 374.75 | 562 | 57,290 | 622 | 63,439 | 686 | 69,913 |

| 30 | 430.2 | 645 | 65,766 | 714 | 72,826 | 787 | 80,257 |

| 32 | 489.47 | 734 | 74,827 | 813 | 82,859 | 896 | 91,314 |

| 34 | 552.57 | 829 | 84,473 | 918 | 93,541 | 1,011.00 | 103,086 |

| 36 | 619.49 | 929 | 94,703 | 1,029.00 | 104,869 | 1,134.00 | 115,570 |

| 38 | 690.23 | 1,035.00 | 105,518 | 1,146.00 | 116,845 | 1,263.00 | 128,768 |

| 40 | 764.8 | 1,147.00 | 116,917 | 1,270.00 | 129,468 | 1,400.00 | 142,679 |

| 42 | 843.19 | 1,265.00 | 128,901 | 1,400.00 | 142,738 | 1,543.00 | 157,303 |

| 44 | 925.41 | 1,388.00 | 141,470 | 1,537.00 | 156,656 | 1,694.00 | 172,641 |

| 46 | 1,011.45 | 1,517.00 | 154,623 | 1,680.00 | 171,221 | 1,851.00 | 188,693 |

| 48 | 1,101.31 | 1,652.00 | 168,361 | 1,829.00 | 186,434 | 2,016.00 | 205,458 |

| 50 | 1,195.00 | 1,792.00 | 182,683 | 1,985.00 | 202,294 | 2,187.00 | 222,936 |

| 52 | 1,292.51 | 1,938.00 | 197,590 | 2,146.00 | 218,801 | 2,365.00 | 241,127 |

| Minimum Breaking Force Factor | Nominal Length Mass Factor | ||||||

| K= 0.405 | W= 0.478 | ||||||