All lifting equipment, no matter it’s shape or size, is subject to the same rules and regulations such as the LOLER Regulation. Lifting gear is used in

dozens of industries around the world for hundreds of varying applications, but many of these involve the lifting of extremely heavy loads.

It’s important to follow the LOLER regulation guidelines so that you keep your workers safe

It’s important to follow the LOLER regulation guidelines so that you keep your workers safe

When the safety of workers is a concern, it’s of paramount importance that the guidelines in place are easy to follow, clear, and applicable to your situation. In this article we will be focusing specifically on the regulations that apply to

lifting slings, but please note that the rules will be the same, if not very similar, to most other pieces of equipment too.

What are the LOLER regulation?

The most commonly referred to regulation that you will find in this industry are the

Lifting Operations and Lifting Equipment Regulations 1998 (LOLER). The regulations are quite general in nature, but this is why they apply to all pieces of lifting equipment, rather than just focusing on specific gear.

LOLER is often referred to in conjunction with the

Provision and Use of Work Equipment Regulations 1998 (PUWER). It is worth noting that both LOLER and PUWER aren’t pieces of legal doctrine themselves, but fall under the

Health and Safety at Work etc Act 1974, which is itself a legal act.

What does LOLER say?

LOLER focuses on four very clear and very specific areas when it comes to lifting operations; operations which may be conducted using lifting slings. Should you be using this equipment for an operation, then you must ensure that all operations are:

- Properly planned

- Completed using people who are competent

- Are supervised appropriately

- Carried out in a safe manner

The regulations state that a lifting operation is '…an operation concerned with the lifting or lowering of a load.’, and that lifting equipment is work equipment used for the lifting of lowering of loads, so clearly a lifting sling will fall easily into both these categories.

What does PUWER say?

PUWER relates specifically to work equipment itself, and requires that:

- Lifting slings are suitable for the operation they are being used for

- They are safe for use and kept in a good, workable condition

- The equipment is only used by people who have the right level of instruction and training

- All operations and equipment have suitable health and safety measures in place

How does this relate to lifting slings?

The first thing to note is that LOLER and PUWER require all lifting operations to be properly planned. This means selecting the right equipment for the job. So, before conducting any operation, be sure to triple check that your lifting sling is the best piece for the job at hand. This is crucial, and you mustn’t use it simply because it’s the only piece of gear that you have.

LOLER also requires that lifting slings only be used by “competent” workers. PUWER takes this one step further, by specifying that the slings must be "used only by people who have received adequate information, instruction and training.” So, ensure that any worker who is involved in the planning, use or supervision of any operation involving a lifting sling is fully aware of exactly how it works.

Another crucial aspect of LOLER that applies to your lifting slings is the requirement for regular and thorough examinations. There are a number of situations to which this implies, which includes:

- Before the first use of your lifting sling (unless you have a Declaration of Conformity which has been made less than 12 months’ prior)

- Where the sling needs installation, re-installation, or assembly at a new worksite

- Where your sling may have been exposed to dangerous or harmful conditions, such as an environment with moisture or chemicals

It’s crucial to remember that lifting slings, while manufactured to be strong and long-lasting, will still suffer natural wear and tear after continued use. It’s imperative that you regularly inspect your equipment to ensure that it remains safe and that you are complying with the rules set out in LOLER.

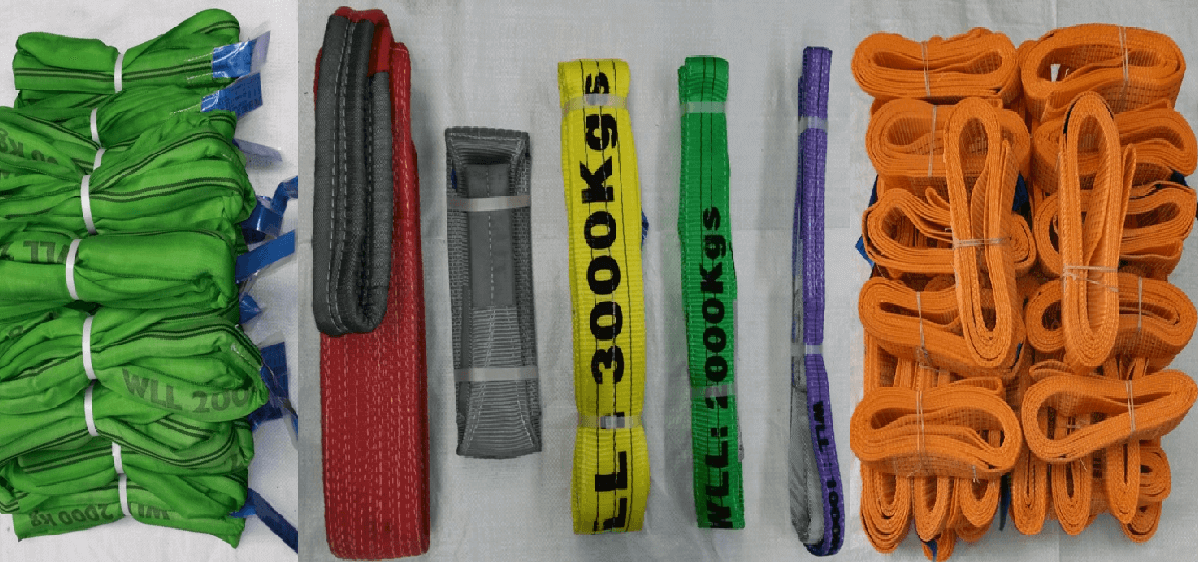

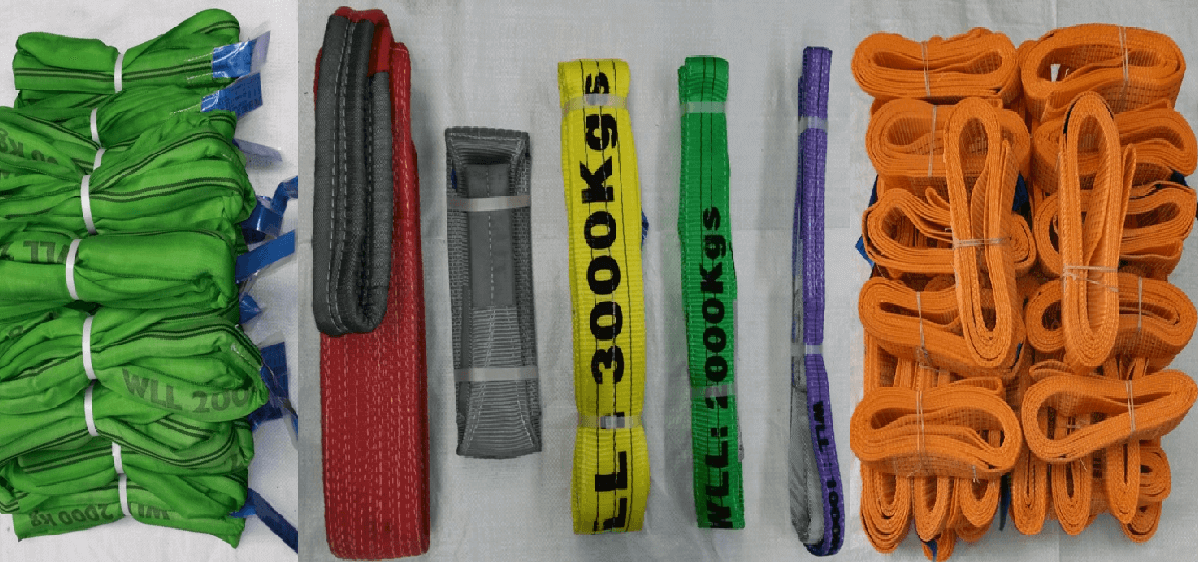

Some of the lifting slings that we manufacture

Some of the lifting slings that we manufacture

Inspecting equipment needs to be done in the right way, and if you are unsure what the best practice is for this, then we are able to provide this service for you. Please find our contact details below if you would like to discuss this further.

Please also refer to the HSE’s

Safe use of lifting equipment for more information on best practice with using lifting slings safely.

Would you like more information on LOLER regulation requirements?

If there are any parts of the LOLER regulation requirements that you have questions on, or perhaps you would like to find out more about our lifting slings, then we would be more than happy to provide information. Please

get in contact with us here.

It’s important to follow the LOLER regulation guidelines so that you keep your workers safe

When the safety of workers is a concern, it’s of paramount importance that the guidelines in place are easy to follow, clear, and applicable to your situation. In this article we will be focusing specifically on the regulations that apply to lifting slings, but please note that the rules will be the same, if not very similar, to most other pieces of equipment too.

It’s important to follow the LOLER regulation guidelines so that you keep your workers safe

When the safety of workers is a concern, it’s of paramount importance that the guidelines in place are easy to follow, clear, and applicable to your situation. In this article we will be focusing specifically on the regulations that apply to lifting slings, but please note that the rules will be the same, if not very similar, to most other pieces of equipment too.

Some of the lifting slings that we manufacture

Inspecting equipment needs to be done in the right way, and if you are unsure what the best practice is for this, then we are able to provide this service for you. Please find our contact details below if you would like to discuss this further.

Please also refer to the HSE’s Safe use of lifting equipment for more information on best practice with using lifting slings safely.

Some of the lifting slings that we manufacture

Inspecting equipment needs to be done in the right way, and if you are unsure what the best practice is for this, then we are able to provide this service for you. Please find our contact details below if you would like to discuss this further.

Please also refer to the HSE’s Safe use of lifting equipment for more information on best practice with using lifting slings safely.