- Wire Rope Products

Wire Rope Products

- Lifting Slings

Lifting Slings

- Cargo & Ratchet straps

Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Lifting Gear

- Height Safety

Height Safety

- Tools

- Assemblies

- Balustrade Wire

Swaging is a process to permanently attach a fitting to the end of wire rope. Swageless fittings can be attached by hand and are a semi-permanent type of end fitting. True swaging is carried out mechanically by larger machines. They assert extreme pressure through special dies to press the fitting onto the rope permanently. These permanently swaged fittings are extremely strong, safe and efficient. Hand held swagers can perform this function.

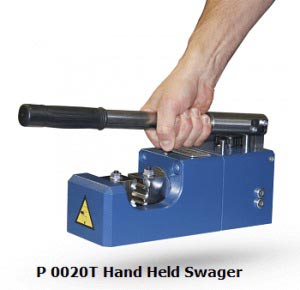

Swaging machines come in many forms with top pressing capacities of over 4000 tonne, these machines are huge. Here we are going to look at the much smaller hand held swaging machine.

Our hand held Swagers are light in weight and compact in design; together with the operating lever doubling as a carry handle they are perfect for site work. They are easy to move around, from tool box, to work van and into factories for use.

Our hand held Swagers are light in weight and compact in design; together with the operating lever doubling as a carry handle they are perfect for site work. They are easy to move around, from tool box, to work van and into factories for use.

This hand held swager can press up to 20 tonne and incorporates an open throat design with a single pillar. These handheld swaging machines use a range of special dies to press the fitting onto the wire rope. The dies are made from tempered & hardened steel, giving them excellent durability which will make them last a long time.

These hand held swagers can fit ‘T’ ferrules up to 6,5 in a single stage swage action. A ferrule up to size 9 can be fitted with a multi-swaging action. UM ferrules can be fitted up to a size number 10 with a multi-swage operation. Closing the die around the rope is easy due to the on board pump. Fitting it in less than 30 strokes of the operating lever.

Operating these hand held swagers is a relatively simple process. Take extra care when using these devices. Because they exert a lot of pressure and could easily crush fingers. The dies slide onto a fitted bolt, where a nut screws on and fixes them down. You should always use a wrench or spanner to tighten up the nut securely.

To open up the dies you will need to open the relief valve to the rear side. Once open you will need to close the relief valve once again. When the wire rope and fitting are in place you can pump the lever/handle back and forth to close the dies and apply the necessary force to secure the fitting to the rope. Open the relief valve to open u the dies and remove your finished wire rope assembly.

A further benefit to these hand held swager is that they can be used horizontally or vertically, providing even more flexibility.

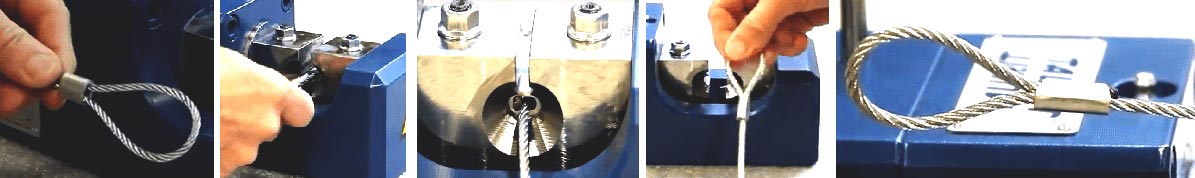

Here is a sequence of pictures showing the various stages of a simple swaging process using hand held swagers. In this case we are forming an eye at the end of a small diameter wire rope with a ferrule. Special thimbles can also be added to give extra strength to the eye if required.

These hand held swaging devices provide the perfect onsite swaging solution. If you need any more details on our range of rope tools or a quotation then simply contact us. We are just a phone call (0138478004) or an email away.

There are no products to list in this category.

There are no products to list in this category.