Our fibre ropes can be supplied by the metre or as a specially constructed assembly such as a rope sling or a tow rope. Hand spliced eyes can be completed in our workshop to suit your needs.

Fibre rope has many uses whether natural or synthetic. Typical uses range from seafaring activities to construction tasks. The range of nylon rope we have available at Rope Services Direct Ltd guarantees the utmost safety and reliability. Our ropes are available in an extensive variety of man-made materials, as well as natural materials so you are sure to find the right product to meet your needs.

HERE IS THE CATEGORY SELECTION OF FIBRE ROPE THAT ROPE SERVICES DIRECT OFFER, IF YOU CAN’T SEE WHAT YOU ARE LOOKING FOR THEN GIVE OUR TEAM A CALL OR CONTACT US HERE WE CAN USUALLY HELP.

Man-Made Or Natural Fibre Rope?

Here at Rope Services Direct, we can supply most kinds of fibre rope, in any length direct to you, whether it is a natural fibre rope or a man-made fibre rope. Below we highlight some of the main properties, advantages and disadvantages of each type of rope. This will to help you to decide upon the best type of fibre rope to suit your intended purpose.

Different fibres can make different types of rope. There are 2 major groups that are; natural untreated fibres and oil based synthetic or artificial fibres.

Some natural fibres are, sisal, cotton, jute, manila and hemp, these days nevertheless, the bulk of fibre ropes are manufactured from oil based synthetic fibres for instance nylon and polypropylene.

The primary distinction between both groups are that natural fibres will rot if saturated over an extended time period. This results from the action of micro-organisms. Man-made fibres are more powerful than natural fibre ropes and won’t be spoiled by micro-organisms. However they are going to deteriorate in bright sunlight and melt at a lower temperature than the natural fibres.

Man-made Fibre Rope

Manmade ropes have overtaken natural fibre ropes in recent years due to their strength, reliability and cost.

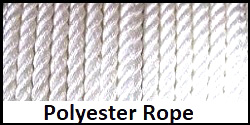

POLYESTER rope has many uses, dockyards, mooring ropes and fishing nets are just a few examples. Other uses include on vehicles, for towing purposes as well as in factories as rope slings for lifting objects.

Made from petroleum based chemicals, polyester is a typical synthetic material. It can be heated to an extreme temperature to produce a chemical reaction. This reaction will then produce polymers/strands which can be made into the desired materials. Polyester is excellent at resisting sunlight, is simple to clean and is quick drying; this rope has the benefit of good resistance to chemicals and oil, mould and mildew and abrasions.

Polyester rope possesses little stretch and so is not going to fare well with shock loading; although has excellent strength qualities, which isn’t lost when wet. This rope is soft to handle and is simple to splice with various end fittings.

Polyprop Rope

POLYPROPYLENE rope, or polyprop as it can often be referred to as, is another synthetic rope. It is probably the most commonly utilised man-made fibre rope. Particularly within the marine, boating, and seafaring industries, including water sports. It’s the only rope which will float, is lightweight, flexible and will not shrink. Polypropylene is also especially resilient to oil, acids and other chemicals. In spite of this polypropylene rope can deteriorate in sunlight however a UV stabiliser may be added to alleviate this.

Polypropylene rope is generally the least expensive man-made rope making it enormously popular.

Chemically made by specialists, polypropylene results from heat treated chemicals processed to create polymers. These polymers are then processed and turned into either fibres or plastics.

Nylon

NYLON rope is tremendously strong, and excellent for absorbing shock loads. Because it may stretch, nylon has the benefit of returning to normal when the load is detached. Nylon creates a strong rope that in general outlives nearly all other ropes. This is mainly due to its resistance to sunlight and chemicals

Towing, fishing, climbing or lifting are common uses for this type of rope.

Chemically made in a factory, nylon undergoes many processes to arrive at the end product we see. Chemists will mix specific chemicals and heat them to extreme temperatures to cause a reaction. Molton nylon is the result which needs further processing. The next step forces the molton nylon through a spinnaret. The end result is tiny nylon fibres.

Natural Fibre Rope

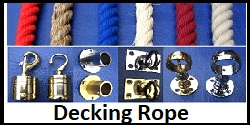

Natural ropes will stretch and shrink back in certain circumstances. These natural ropes appear in countless different thicknesses from 2mm twine to 40mm ropes. This rope typically comes on reels with lengths of up to 220 metres long and so ideal for the larger ropes. So there should be something available to suit your needs. Natural fibre ropes are commonly used as decking rope and for defining other garden areas.

Types of Natural Rope

COTTON rope is extremely popular in handicraft work because it may be dyed to a specific colour without difficulty, additionally it is utilised for packaging, picture hanging and sash cords on window blinds. Circus artists occasionally utilize cotton ropes for their trapezes as well as climbing ropes. Cotton rope, twine as well as cord is incredibly soft and comfortable to work with. It’s lightweight as well as stretchy, however it isn’t resistant to oil, chemicals and water and so unsuitable for some purposes.

JUTE rope is produced from the vegetable fibre (corchorus olitorius and corchourus capsularis) the fibres are taken out from the stem plus external skin by using a method known as retting, this is where bundles of the fibres are submerged in water after which it is stripped of the non-fibrous material, fibres are next pulled from the stem. Fabrics such as hessian and sacking are the primary uses of jute nowdays. Jute is strong and rough in texture, so could be harsh on the skin if handles frequently.

Other Natural Ropes

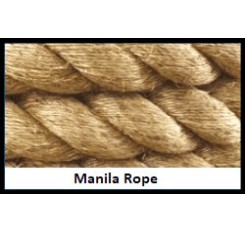

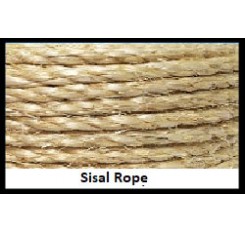

SISAL rope is made out of fibres belonging to the agave plant, the plants typically possess a life-span of 7-10 years, every sisal plant will churn out about 200 leaves within its natural life, from which the fibres are taken, and each leaf may give 1000 fibres. Sisal is tough and durable and possesses the capability to stretch; it is additionally resilient to salt water. Handicrafts and decking are popular uses of sisal rope. Sisal however will not last as long as manila, however is lighter in colour.

MANILA rope is the most extensively utilised natural rope, the fibres are extracted from the manila hemp plant, known as abaca, it is related to the banana plant (not true hemp) however the fruit is inedible .The long fibres from overlapping foliage are removed after the plant has matured and cut down. Manila fibres are strong and hard-wearing. Fabrics and paper goods use the finer fibres whilst twines and ropes use the thicker, stronger fibres. Manila is resilient to salt and sunlight which makes it popular within the marine industry. Decking rope is one of the most popular uses of manila rope.

Fibre Rope History

Natural fibre rope has been used for thousands of years. The proof of which is seen in 20,000 year old cave paintings as well as samples from Egyptian times which can be found in many museums.

Flax, grasses, vines and reed fibres were commonly used in the early days of rope. They were weaved, twisted or plaited together. Natural progression or the rope development led them to use animal hair and leather to make stronger, longer lasting ropes, however the ropes were of relatively short length and so useless for some tasks.

The middle ages saw the introduction and development of rope walks; these were very long areas many strands were laid out across the whole length and then twisted tightly together with hemp fibres feeding out from a wheel at the end of the walk, this enabled much longer rope strands to be made. As time went on these strands were twisted together to form a thicker, stronger rope.

Over the year different plant fibres were used for different tasks depending on their characteristics, hemp, sisal and jute were and are still used. Manila became a popular natural rope in more recent years probably because of its smoother, softer nature.

Although natural rope is still used man-made fibre ropes have been increasing in dominance since the 1950’s. These ropes are made from nylon, polyester or polypropylene, the fibres of which are made from chemicals and their reactions with each other. Man-made rope is often cheaper to produce and have some better properties to natural rope.