- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

There are many different kinds of annealing machines available. From small hand held devices, larger manual annealing machines to automatic annealing machines. Rope Services Direct can supply the former two types at competitive prices. Check out our other rope tools here.

In short, annealing is a process using extremely high heat to alter the malleability of metal. Metal grains will re-crystalize under the red hot heat. This softens the metal for working easier. You can find out more about annealing and the definition here

In short, annealing is a process using extremely high heat to alter the malleability of metal. Metal grains will re-crystalize under the red hot heat. This softens the metal for working easier. You can find out more about annealing and the definition here

Wire rope annealing is often referred to as fuse and tapering due to the fact that during the annealing process the strands within the rope get so hot that they fuse together, the rope is twisted and pulled at the same time which then breaks the rope into two. This tapers the end of the rope slightly whilst completely sealing the ends of the strands. Protect the rope from brittleness by cooling slowly. A fuse and tapered rope will not untwist.

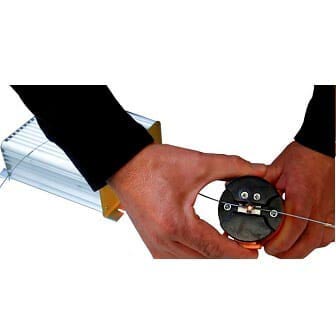

There are different ways to anneal a wire rope. Although it can be rather dangerous as you are working with extreme heat. Rope Services Direct can supply specialist annealing machines. Annealing is much easier and safer with these machines. The machines use an electrical currents to supply the heat to anneal the rope. When the correct temperature is reached the rope is twisted and pulled. Completed by using the wheels and handles to slightly round and fuse the wires. The tapered end can be altered by adjusting the distance between the clamping chucks.

Optimize your annealing process with one of our machines. Giving the best results time after time. Inserting and clamping the rope is quick and easy. It can be inserted from above and clamped by a couple of eccentric levers. The AV annealing machines are safe to use. This is thanks to a foot pedal which operates the heat.

For wire rope up to 2mm in diameter we offer the LGK 02 annealing machine which is great for smaller tasks and site work. The vibration resistant unit uses high frequency control with over-voltage protection.

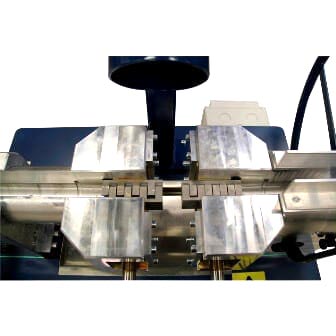

The AV range of annealing machines has three models, the AV 30, AV 45 & AV 65. The number references the maximum diameter of wire rope the machine can handle. I.e. 30mm, 45mm & 65mm. These machines are straight forward to use. They have rope holding jaws which do not need any alteration for different rope diameters. The AV annealing machine range makes short of the annealing time. Manual adjustments to the taper is possible during twist off. So you will get your preferred shape and length.

All models come with a safety glass which offers excellent protection to the user from sparking and heat. A ventilation hose will exhaust out the smoke for better ventilation.

Please take a look below at each model to see the specific details for that model; let us know if you need more details.

These are lightweight machines for ropes less than 2mm in diameter. They create few sparks and no loose wires. The LGK 02 has good safety protection thanks to a completely enclosed low volt control box with double insulation. Using a high frequency control it has overload and over voltage protection with an auto-delay function. These annealing machines also boast vibration resistance.

Capable of annealing wire ropes with diameters up to 30mm, the AV30 incorporates four power options to optimize the heat and taper options to suit your needs. There is a release device on the handle of the pulling chuck enabling a more ergonomic work position. Exhaust ventilation is recommended. Wheels are an optional extra but can aid move-ability. The AV30 annealing machine is compact and easy to operate with individually operated parameters.

The AV 45 annealing machine boasts 6 different power levels enabling better control of the fuse and taper and shortening the time taken. Annealing wire rope up to 45mm diameters is no problem for the AV 45 and with ergonomic options such as combining a handle with the wheel on the pull chuck, handling couldn’t be easier. A safety glass is positioned to offer spark protection to the user. Wheels are an option and ventilation is recommended.

Capable of working with ropes up to 65mm in diameter the AV 65 annealing machine incorporates quick clamping levers to facilitate rapid insertion of the wire rope, even from above. There are special dies are tensioned so they do not need to be changed for different diameters of rope. The foot operated current delivery system enables free hands to operate the machine.

The hot working area is enclosed with a fume trapping hood and a tray collects any ashes and debris from the annealing process. The AV 65 comes ready for external ventilation, optional water cooling and with wheels as an extra option. A 65mm rope will take approximately 11 minutes to anneal properly.

There are no products to list in this category.

There are no products to list in this category.