- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

Tested and certified for lifting applications as well as tensioning the stainless lifting turnbuckle with jaw & jaw has a working load limit range up to 7600kg.

These 316 stainless rigging screws with jaw and jaw end fittings enable easy anchoring and attachment of other products. With a sleek, polished finish the aesthetics are great too.

Inspection holes in the barrel gives you the ability to check for the minimum thread engagement. Bronze threaded inserts are used on models 5/8” and above to help prevent galling. The jaws have no welds thanks to being made from solid stainless steel.

These precision-engineered stainless lifting rigging screws combine high quality materials with rigorous testing standards to ensure safe, dependable operation in the harshest environments.

Made from quality grade 316L stainless steel to EN10088 1.4404, corrosion resistance is top notch thus ideal for marine environments, water utilities, chemical installations, off shore and general lifting tasks.

Unlike many other turnbuckles and rigging screws these have been tested and certified to be used safely in lifting applications. Tested to 2xWLL, a safety factor of 6:1 and made in accordance to the machinery directive 2006/42/EC you can be assured these turnbuckles are robust and made to high standards.

If you require formal paperwork, inspection certs conforming to BS EN 10204 3.1 can be provided.

Rope Services Direct supply a wide range of turnbuckles and rigging screws, however only specific models are certified for lifting. We have 3 stainless turnbuckles with various end fittings as well as 4 green pin turnbuckles which can all be utilised for both lifting and tensioning applications. Unless stated turnbuckles and rigging screws should only be used for tensioning tasks.

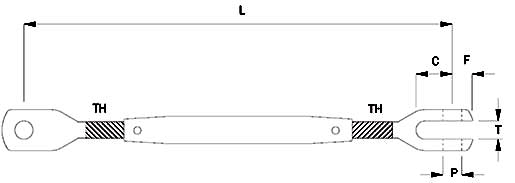

| Thread (″ unf) |

WLL (kg) | Wire Diameter (mm) | P (mm) | C (mm) | T (mm) | Min L (mm) | Max L (mm) | Weight (g) | Product Code |

| ¼ | 200 | 3 | 6 | 12.5 | 6.2 | 135 | 205 | 80 | RSFF03-WLL |

| 5/16 | 325 | 4 | 8 | 17 | 7.9 | 165 | 240 | 170 | RSFF04-WLL |

| 3/8 | 500 | 5 | 9.5 | 19 | 9.9 | 200 | 300 | 282 | RSFF05-WLL |

| 7/16 | 700 | 6 | 11 | 20 | 10.9 | 220 | 330 | 398 | RSFF06-WLL |

| ½ | 825 | 7 | 12 | 25 | 12.7 | 260 | 390 | 614 | RSFF07-WLL |

| 5/8 | 1325 | 8 | 14 | 28 | 13.5 | 325 | 480 | 1260 | RSFF08-WLL |

| 5/8 | 1325 | 10 | 16 | 32 | 15.8 | 345 | 500 | 1434 | RSFF10-WLL |

| ¾ | 1825 | 12 | 19 | 38 | 17.8 | 400 | 570 | 2418 | RSFF12-WLL |

| 7/8 | 2500 | 14 | 22 | 45 | 22 | 450 | 640 | 3577 | RSFF14-WLL |

| 1 | 3300 | 16 | 25 | 50 | 25 | 520 | 760 | 5340 | RSFF16-WLL |

| 1.125 | 4300 | 19 | 28 | 58 | 28.2 | 585 | 855 | 5618 | RSFF19-WLL |

| 1.25 | 5500 | 22 | 32 | 64 | 31.5 | 635 | 920 | 7711 | RSFF22-WLL |

| 1.375 | 7600 | 26 | 35 | 70 | 34.8 | 715 | 1040 | 14085 | RSFF26-WLL |